The Boiling Frog Parable

Overhead Crane are Really Easy…

Until They’re Not ?!?!

Overhead bridge cranes aren’t rocket science. Most of the time, EOT crane projects are really pretty simple and therein lies the problem. Buyers and sellers get lulled into a state of complacency and don’t realize when they’re entering the twilight zone.

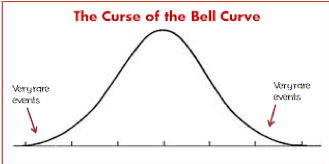

After 40+ years as a crane builder, I’ve determined that the EOT crane world can be viewed as a Bell Curve. The overwhelming majority of cranes built reside in the center portion of the curve. This creates a false confidence that all crane projects are “no-brainers.” Unfortunately, now and then we walk into one of those projects that just seem like they were cursed from the beginning.

In reality, these projects are not cursed but just a collection of characteristics that when they occur together spell trouble. It reminds me of the Frog in hot water parable. The story goes that if you were to drop a frog into boiling water it would react to the scalding temperature and immediately jump out. Conversely, if you put a frog into a pot of water at room temperature and slowly bring it to a boil, it would never sense the danger until it’s too late. I believe this to be the case with most “cursed” projects.

With this in mind, I recently sat down and made a list of questions that can serve as a barometer of potential risk. Any one of these factors should be a warning that “we’re now swimming in the deep end of the pool,” and if we find we’re saying yes to multiple questions, it’s time to enter the project with a real sense of caution.

To date, I’ve put together about 40 questions and these questions can be grouped into seven categories. In the following weeks, I will write a separate article for each of the groups below. They are as follows;

The Ultimate Question

Dimensional Requirements

Environmental Issues

Production Requirements

Electrical Issues

Chronic Existing Problems

Miscellaneous Items

In the remainder of this paper, I will list and explain each question. By the way, I have not figured out any numeric point value for the questions such that if after you go through the list anything greater than say 70 points is dangerous. The best I can do is to caution you that the more you take the non-default answers on my checklist, the more cautious you should be.

GROUP A: THE ULTIMATE QUESTION

This question is so important, that it’s the one and only question of the group and it’s as important as the whole remainder of the checklist put together.

1. Is this a “Process” Crane?

The EOT crane world can be divided into two hemispheres;

a) Industrial Cranes

Industrial Cranes consist of CMAA “A,” “B,” “C” and “D” cranes. When Industrial grade cranes go down, it’s a big pain but the plant continues to run. Even the CMAA 70 “D” spec states that;

In this type of service, loads approaching 50 percent of the rated capacity will be handled constantly during the working period.

Industrial grade cranes probably represent over 90% of the crane units (not dollars) manufactured.

b) Process Cranes

A “Process” crane is an integral production tool. When the crane goes down, production stops, huge numbers of workers are sent home. Typically, Process Cranes are CMAA Crane Class E- Severe Service or F- Continuous Service cranes or cranes built to AIST (Association for Iron and Steel Technology) TR#6 Steel Mill Specification.

Process Cranes are almost always 6 or even 7 figure purchases.

In other words, Process vs Industrial crane is a function of duty cycle and NOT capacity. Although the dividing line between CMAA D and CMAA E is not an official differentiator between Process and Industrial Crane, practically speaking it’s a good defacto line of demarcation.

As a reference, here are the CMAA paragraphs describing the two classes that boarder the dividing line between Industrial Crane and Process Cranes;

CMAA D- Heavy Service

This service covers cranes which may be used in machine shops or paper mill machine rooms, etc., where service requirements are moderate. In this type of service, the crane will handle loads which average 50 percent of the rated capacity with 5 to 10 lifts per hour, averaging 15 feet, not over 50 percent of the lifts at rated capacity.

CMAA 70 Class E- Severe Service

This type of service requires a crane capable of handling loads approaching a rated capacity throughout its life. Applications may include magnet, bucket, magnet/bucket combination cranes for scrap yards, cement mills, lumber mills, fertilizer plants, container handling, etc., with twenty or more lifts per hour at or near the rated capacity.

Conclusion of GROUP A: The Ultimate Question

One of the most common misconceptions that crane people incur when talking to non-crane people is the confusion between the terms “heavy” and “heavy-duty”. “Heavy” refers to capacity and not duty cycle. Conversely, “heavy-duty” refers to a combination of cycles per hour in conjunction with average percent of capacity lifted. There are “heavy-duty” 3-ton cranes and “light-duty” 500-ton cranes and the distinction is critical.

NEXT ARTICLE, #2:

Here are the questions that we will be covering in the next follow-up article.

GROUP B: Dimension Issues;

Crane span greater than 60 ft-

Lift greater than 30 ft

Runway support centers greater than 30 ft

Runway support centers greater than 30 ft

Runway greater than 400 ft long

Special End Approach Needs

Special crane “envelope dimension” top of runway rail to lowest overhead obstruction

Special floor to bottom of girder requirement

Special floor to hook up dimension

Special hook below floor level dimension

By the way, a full PDF copy of the questionnaire is available below.