PART 2: It's Not As Easy As You Think

Who’s Rules Rule

This question of what rules to use should be easy to answer. You should be able to call up a crane inspection company and ask for a price to get an Annual OSHA crane inspection and know exactly what you’re getting.

The pivotal word here is “should.” Unfortunately, the above request is fraught with land mines. Here’s why.

Let’s start with a few facts to illustrate the problem.

There is no such thing as an “Annual OSHA crane inspection,” even though that’s what everyone calls them.

OSHA only requires double girder, top running cranes be inspected (see OSHA Clarification Letter dated 5/23/84 by Director B. Miles Jr.). What does that mean for all your other cranes? Should you get them inspected? If so, how frequently and to what extent?

OSHA 1910.179(J) only has a total of 667 words, just a little more than one typewritten page, so how could that document delineate the necessary detail to inspect an overhead crane? Spoiler Alert…It can’t, and it doesn’t.

As an industry, most not only can’t define exactly what an overhead crane consist of, we can’t even say for sure what rules and regulations define the process.

OSHA 1910.179 Overhead and Gantry Cranes, is comprised of about 6,800 words or about 15 typewritten pages, while the Inspection Section 1910.179(J) being only 667 words. There obviously must be other reference sources governing the inspection process. So, what are the document(s) that govern EOT Overhead Crane inspections? This is not an easy question. To illustrate this point, let me tell you a quick story.

ATTEMPTING TO WRITE THE INSPECTORS TEST

In 2018, as the Executive Director of the CCAA (Crane Certification Association of America) I was one of four committee members charged with designing a written test for the certification of EOT Overhead Crane Inspectors. The group consisted of the following experienced crane people.

The first person was a licensed PE, with over fifty years of crane inspection experience. The second was a twenty-year owner of an independent overhead crane inspection company, originally trained by and worked for P&H ProCare service group. The third was an overhead crane inspection company Service Manager with over ten years’ experience and lastly me with over four decades’ experience as an owner of a crane manufacturing and inspection company.

With four people comprising over 100 years of crane inspection experience, we managed to spend almost a half-day in a heated discussion as to which documents were the appropriate specifications we should be using. Common sense says this should have be the easy part of the project, but in fact it was the most difficult.

If four overly qualified experts, with over a hundred years’ experience, cannot agree on which rules govern the overhead crane inspection process, how in the world can the average crane owner know?

OSHA’S DOCUMENTATION HISTORY

OSHA is really two separate worlds; CFR 1926 is for Construction, and CFR 1910 governs General Industry. For our discussions, we are exclusively referring to the General Industry 1910 Specification.

Section 1910.179 covers Overhead and Gantry Cranes and subsection 1910.179(J) is the section covering crane inspections. As we established above, Section OSHA 1910.179(J) contains only 667 words. The OSHA authors wisely deferred to SME’s (subject matter experts) from each industry by adopting the industry consensus standards (in our case, CMAA 70 and ANSI B30.2). This was done through a process called “Incorporation by Reference.”

OSHA 1910.6 INCORPORATION BY REFERENCE

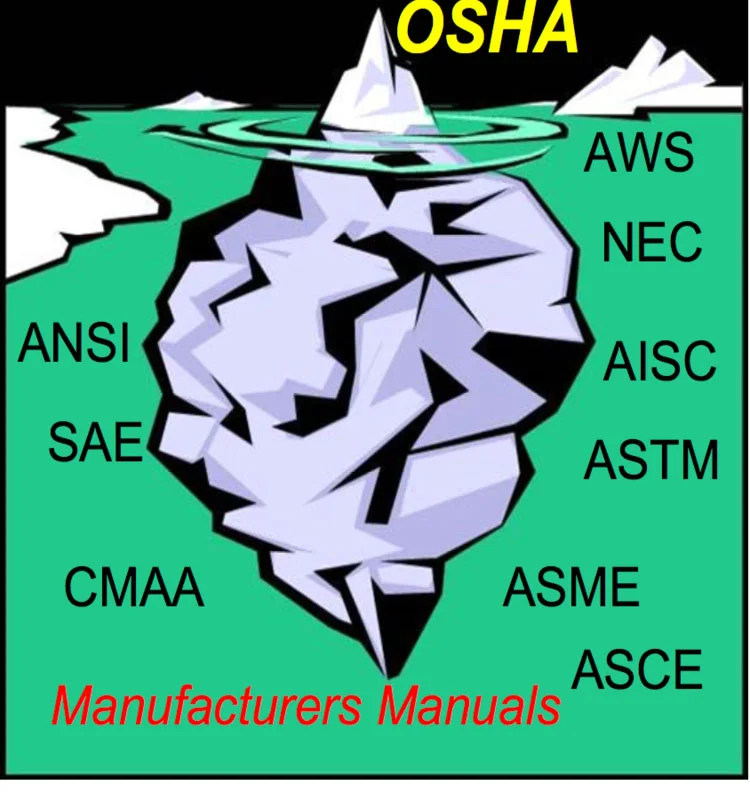

There’s a lot more than you see at the surface

OSHA 1910 has a little-known section, Paragraph 1910.6 Incorporation by Reference. The essence of Incorporation by Reference is that it takes a list of specifications, regulations, and consensus standards and gives them the full force of law. They function as if directly written into the CFR 1910 document.

Although a short section, 1910.6 dramatically widens the scope of 1910. The three words, “Incorporation by Reference” actually incorporates 197 additional specs and consensus standards. With a conservative guess of 100 pages per referenced document, this would add 19,700 pages to the OSHA standards. This makes for a massive difference in interpreting the requirements of OSHA.

Luckily, most of the 197 referenced documents are irrelevant to overhead bridge cranes and can be ignored. For a complete list of the 197 papers go to the OSHA website;

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.6.

OSHA 1910.6 references that are relevant to EOT Cranes

ANSI B30.2 Overhead and Gantry Cranes, 1943 and 1967. Although 1910 specifically calls out the 1943 and 1967 editions of B30.2, these versions are virtually unobtainable. In subsequent OSHA Letters of Clarification, OSHA has ruled that current versions can be used if they are equal to or more stringent. Using the current version makes life easier, although it’s hard to determine if the current version is “equal to, or more stringent” when the 1943 and 1967 versions are not available.

CMAA 1B61 (A 50 year old typo, probably EOCI 61)

I called CMAA to find out what CMAA 1B61 was, only to find out that they have never heard of the document. I assume that this is a typo and that the OSHA writers were referencing the “pre-CMAA” organization called the “EOCI,” Electric Overhead Crane Institute, and their spec issued in 1961. Again, this document is virtually unavailable. Therefore the current edition of CMAA 70 is usually used.ANSI A90.1-69 Safety Standard for Manlifts, IBR approved for §1910.68(b)(3) (specific to crane inspection and service)

ANSI A92.2-69 Standard for Vehicle Mounted Elevating and Rotating Work Platforms (specific to crane inspection and service)

ANSI A120.1-70 Safety Code for Powered Platforms for Exterior Building Maintenance (specific to crane inspection and service)

This “Incorporation by Reference” of just two documents (ANSI B30.2 and CMAA 70) leads to a domino effect. Both ANSI B30.2 and CMAA 70 in turn incorporate a number of other consensus standards. These additional reference documents, because of “Incorporation by Reference” now also have the full force of law of OSHA with enforcement by the US Department of Labor.

Beware, this list is going to get pretty hairy as you will soon see.

ANSI B30.2-2016 Referenced Overhead Crane Documents

AIST Technical Report No. 6, Specification for Electric Overhead Traveling Cranes for Steel Mill Service

ANSI Z244.1, Safety Requirements for the Lock Out/Tag Out of Energy Sources

ANSI A14.3, Safety Requirements for Fixed Ladders

ANSI A1264.1, Safety Requirements for Workplace Floor and Wall Openings, Stairs, and Railing Systems

ANSI Z241.2, Safety Requirements for Melting and Pouring of Metals in the Metalcasting Industry

ANSI Z535.4, Product Safety Signs and Labels

ANSI/ASCE Design Guide 7, Minimum Design Loads for Buildings and Other Structures

ANSI/ AWS D1.1, Structural Welding Code Steel

ANSI/ AWS D14.1, Specification for Welding of Industrial and Mill Cranes and Other Material Handling Equipment

ANSI ECMA 15, Specifications for Cable-less Controls for Electric Overhead Traveling Cranes

ANSI/NFPA 70, National Electrical Code

ANSI/SAE Z26.1, Safety Glazing Materials for Glazing Motor Vehicles and Motor Vehicles Operating on Land Highways (for Crane Cab windows)

AISC ASD Manual of Steel Construction

AISC LRFD Manual of Steel Construction

ASME B15.1, Safety Standard for Mechanical Power Transmission Apparatus

ASME B30.9, Slings

ASME B30.10, Hooks

ASME B30.16, Overhead Hoists (Underhung)

ASME B30.20, Below-the-Hook Lifting Devices

CMAA Specification No. 70, Specifications for Top Running Bridge and Gantry Type Multiple Girder Electric Overhead Traveling Cranes

CMAA 7-2016 Referenced Overhead Crane Documents

AISC ASD Manual of Steel Construction

AIST Technical Report TR-01, DC Mill Motors

ANSI ASC A14.3, Safety Requirements for Fixed Ladders and Workplace Surfaces

ASCE/SEI 7, Minimum Design Loads for Buildings and Other Structures

ASME B30.2, Overhead & Gantry Cranes (Top Running Bridge, Single or Multiple Girder, Top Running Trolley Hoist)

AWS D14.1, Specification for Welding of Industrial and Mill Cranes and other Material Handling Equipment

CMAA Overhead Crane Inspection and Maintenance Checklist

CMAA Specification No 79, Crane Operator's Manual -

ECMA 15, Specification for Cable-less Controls for Electric Overhead Traveling Cranes

ECMA 25, Specification for AC Inverters for use on Electric Overhead, Monorail, and Gantry Traveling Cranes

NFPA 70 - National Electrical Code,

The above three lists, OSHA, B30.2 and CMAA 70, add a total 36 Specs and Consensus Standards to the OSHA standards for Overhead Cranes. To be fair, there are a couple of duplicates between the lists. I have also left off several more esoteric standards, such as the AGMA Gear Specs and the IEEE Power Distribution Specs. These are specs that I feel are beyond the scope of the article.

This document list lends a whole new meaning to the question, “… can you give me a price on an OSHA crane inspection?” If you think an OSHA overhead crane inspection all encompassed in OSHA 1910.179, you are in for a rude awakening.

Bottom line, here are the critical questions you need to be asking;

What level of inspection are you requesting, simply visual or tearing down things like gearboxes??

Have you clearly indicated the level of inspection in writing, and is it adequate to keep your people safe, and keep you safe from OSHA and legal liability?

Are you and your inspection company on the same page and if you think so, where can you point to this fact in “black and white?”

In the Part 3 article I will prioritize the above list of EOT Crane documents into;

Primary inspections docs

Secondary inspection docs

Reference docs

Prioritizing the list will provide for more digestible chunks of information to consume.