Overhead Crane Technician Qualifications

WHAT ARE THE JOB QUALIFICATIONS FOR AN EOT OVERHEAD CRANE TECHNICIAN

Here are the qualifications of an Overhead Crane Technician. Per my previous posts, I’m a big fan of CMAA 78-2015: Standards and Guidelines for Professional Services Performed On Overhead Traveling Cranes (a book title only an engineer could dream up). CMAA 78 is the least known spec in the Overhead Crane world but probably the most important. It’s the document, not OSHA 1910, not CMAA 70 and not any of the B30 documents, that, in black and white, provides basic guidance to the crane owner regarding owner specific responsibilities.

This includes;

Technical qualifications for Overhead Crane Technicians

Technical qualifications for Overhead Crane Inspectors

Qualifications for Overhead Crane Operators (actually CMAA Spec 78 and 79)

Overhead Crane inspection requirements including;

Specifically, what types of cranes/hoists are to be inspected

Specifically, what components are to be inspected

Specifically, who’s qualified to perform an EOT Crane Inspection

Specifically, how frequently are Overhead Crane Inspections required

You may have noticed that I have probably overused the word “specifically.” My point is that Spec 78 is the first and only place that provides the crane owner with unambiguous information regarding what’s expected of him. Thank-you CMAA, it’s about time somebody did this and it really should have been done by OSHA and if not OSHA then by the appropriate B30 committees… but it wasn’t. So again, thanks to the CMAA Spec’s 78 and 79 committees.

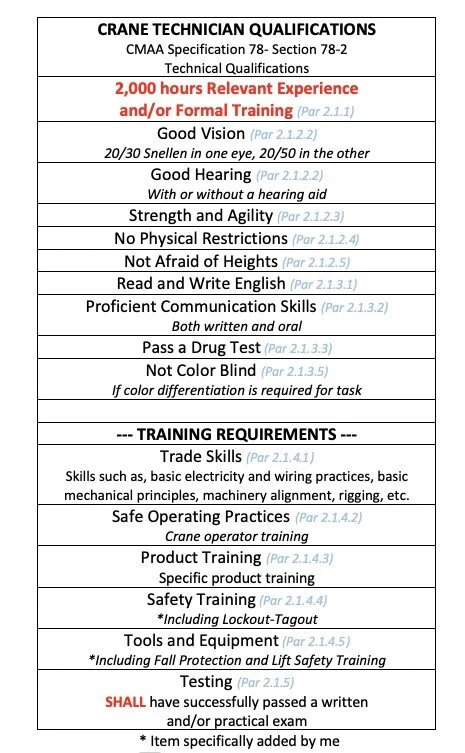

Per my last post, here are the requirements (per Spec 78) for a qualified Overhead Crane Tech.

Crane Technician Qualifications, per CMAA Specification 78

Note, these are the requirements for an Overhead Bridge Crane Technician and not the qualifications required for an EOT Crane Inspector. Per the CMAA 78 definitions, these are two different job titles. It’s not that one person can’t do both, but it’s also concievable that a person can be qualified to do one and not the other. I will go into the Crane Inspector requirements in the next post, they are more stringent than Technician requirements.

It’s important to call your attention to six points in particular;

PARAGRAPH 2.1.1 WORK EXPERIENCE REQUIRES;

A crane technician should have a minimum of 2,000 hours of relevant work experience and training related to maintaining, inspecting, servicing, repairing and modifying cranes. This individual shall have a working knowledge of how to identify deficiencies, and make repairs to mechanical, structural, and electrical crane components and associated hoisting equipment. Under no circumstances shall an individual be permitted to perform repairs that has not received appropriate training and cannot demonstrate a working knowledge of the codes, regulations and the product being repaired.

PARAGRAPH 2.1.4 Required Training;

The technician shall have received formal training in the areas of their trade or discipline and areas of expertise.

Beware, if your training did not require a written test and therefore the training program has no paper trail, at the very least be sure to have a “sign-in” sheet and keep those sheets in a safe place for future reference.

PARAGRAPH 2.1.4.2 Safe Operating Practices of the Crane;

Receive classroom and practical training on basic operating principles and methods, i.e., rigging; hand signals; starting, stopping and controlling loads; do's and don'ts for safe operation, etc.

In other words, the service tech must be a trained and competent Overhead Crane operator. Further, some proof of the training needs to be on file for future reference.

PARAGRAPH 2.1.4.4 Safety;

Training on all aspects of job-site safety and safe work practices not limited to proper crane operation and the understanding of crane controls or additional on-site training as required by the customer.

Among the many safety training topics required, the undisputed king here is an “in-depth” knowledge of Lockout-Tagout, with documented proof of formal training. It is my experience that poor or inadequate execution of LOTO is the number one cause of EOT Crane Technician and Inspector accidents. After all, the “E” in EOT stands for Electric!

PARAGRAPH 2.1.4.5 Tools and Equipment;

Training on proper and safe operation of work tools and equipment such as ladders, man-lifts, jacks, hand tools, meters, etc.

The essentials here are documented proof of Fall Protection and Manlift training.

PARAGRAPH 2.1.5 Testing

Technicians shall be able to successfully demonstrate retained knowledge and proficiency by passing a written and/or practical examination on topics determined by the OEM or Purchaser. Service provider shall be able to present documentation of successful completion of training for topics that require examination.

Hopefully by now you’ve realized the absolutely essential posession of;

CMAA 78-2015 Standards and Guidelines for Professional Services Performed On Overhead Traveling Cranes

It’s about fifty bucks and it’s available at;

Click Here to get CMAA Spec 78

While your at it, get a copy of CMAA 79 Overhead Crane Operators Manual. We’ll be going over that next.

Any questions or comments, please send them to: Larry@OvereheadCraneConsuting.com